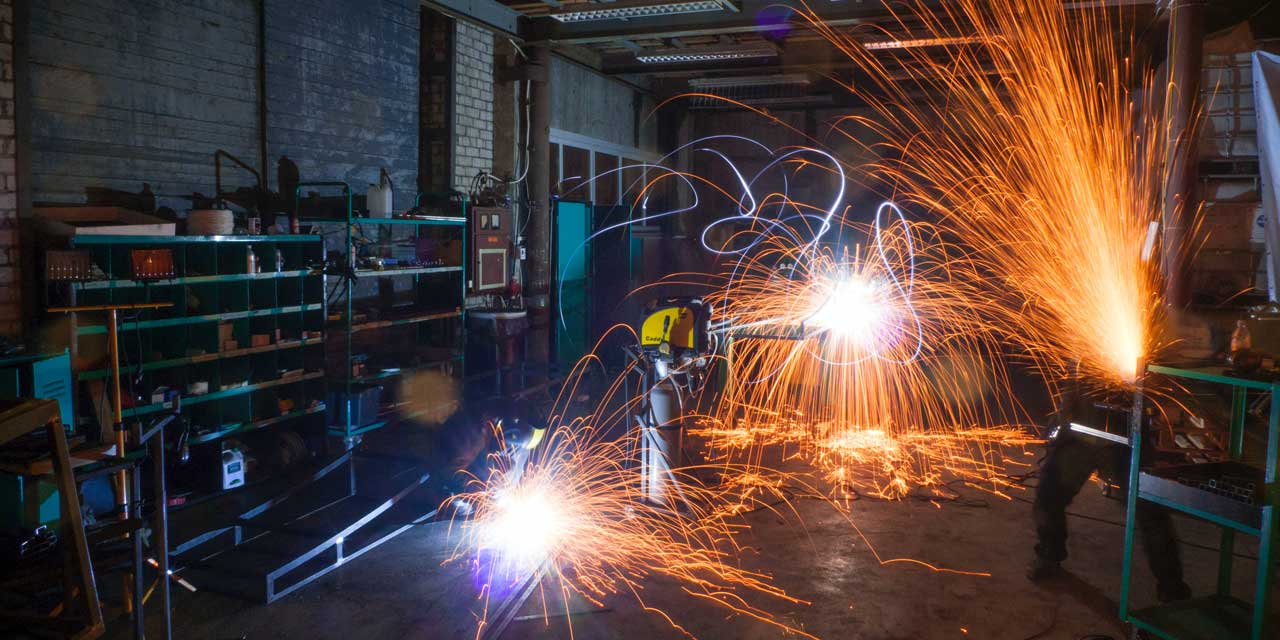

Entry-Level Welding Assessment

With a growing demand for skilled workers, we see an increasing need for welding professionals each year. Employers from welding shops, assembly lines, and mechanic workshops, are all searching for employees with welding skills. The key to hiring qualified welding professionals is thorough, data-driven pre-employment skills assessments.

Whether potential candidates are MIG, TIG, or SMAW welders, every new hire should know basic safety rules, blueprint and instructional reading, and the fundamentals of each welding type. With our entry-level welding assessment test, you can conduct a welder skills assessment and ensure you are hiring the best candidates with adequate skills and knowledge. (And if you’re looking for more advanced welding candidates, we have a pre-employment test for that, too!)

Our Entry-Level Welding Assessment Helps You Hire with Confidence

Nocti Business Solutions (NBS) tests are created with panels of industry experts. We subject our welding assessments to rigorous quality testing to ensure test results are reliable, accurate, and fair. In addition, unlike other basic welding knowledge tests, NBS’ welding evaluation measures soft and hard welding skills, so you can trust that job candidates who pass this welding evaluation will thrive in your workplace.

The NBS entry-level welding assessment test is a comprehensive evaluation of welding fundamentals:

- Safety

- Welding Symbols and Blueprints

- Oxyfuel Cutting (OFC)

- Arc Cutting Process (Carbon Arc and Plasma Arc)

- Physical Characteristics and Mechanical Properties of Metals

- Weld Fit-Up and Quality

- Shielded Metal Arc Welding (SMAW)

- Gas Metal Arc Welding (GMAW) and Flux Cored Arc Welding (FCAW)

- Gas Tungsten Arc Welding (GTAW)

For more details about the subjects covered in the entry-level welding assessment, testing materials, or to view sample questions, please review our Assessment Blueprint.

Three Benefits of our Entry-Level Welding Assessment

Hundreds of employers have trusted NBS with their pre-employment testing since 1999. In particular, our welder skills assessment offers a variety of benefits.

1. Promote Welding Safety

Never place a worker in a welding environment if they do not have the skills or knowledge to keep that environment safe. Fifteen percent of our assessment focuses on the many safety aspects of welding to ensure any potential hire possesses the necessary safety knowledge for any welding position.

2. Gauge Basic Welding Skills and Knowledge

By using our entry-level assessment, you and employers like you can accurately identify whether a candidate has the welding skills and knowledge required for the position. The welding assessment test provides quantifiable data so you can identify which candidate has a higher knowledge and skill level, making it easier to hire the right person.

3. Optimized New-Hire Training Efforts

In a high-demand field with a growing skills gap like welding, it’s hard to turn willing workers away just because of a test score. Fortunately, when you use NBS pre-employment skills testing, you don’t have to.

NBS designs tests to help you make informed hiring decisions—and that includes identifying future employees with outstanding potential who may just need a little additional support. Because this assessment is not a pass-fail test, employers use results to identify areas where a candidate’s knowledge is lacking and design a training program to improve those areas.

Keep in mind, we don’t recommend employers make hiring decisions based solely on test results. However, if properly implemented at the entry-level, technical skill assessments have proven to create better worker retention, morale, and productivity.

Use Pre-Employment Testing Amid the Growing Demand for Welders

With their skills in high demand, the future is bright for skilled and certified welding professionals.

Welders help maintain our nation’s infrastructure by rebuilding bridges, highways, and buildings. A welder’s basic skills are similar across multiple industries and they may easily shift from one industry to another depending on demand. New jobs are projected in the construction and manufacturing industries.

The future can be just as bright, if not brighter, for welding employers. As an older generation of workers approaches retirement, workforces with skilled welders are going to be in high demand. Now is the time to prepare and build a superior workforce to meet that coming demand.

Build a Superior Welding Workforce with NBS Pre-Employment Welder Skills Assessment

At Nocti Business Solutions, we provide technical skill assessments to a wide variety of businesses throughout the United States. Each of our assessments is designed to help an organization maintain safety, optimize training programs, and drive success.

If you employ welding professionals, partner with NBS to ensure your hiring process is efficient and impactful. Contact Nocti Business Solutions today to begin building a superior workforce with our welding skills assessment today.

Recent Comments