Manufacturing Skill Standards Council (MSSC) is an industry-led, non-profit training, assessment, and certification system focused on the core skills and knowledge needed by frontline production and material handling technicians. Based on industry-defined and federally endorsed standards, MSSC has developed stackable certifications that offer entry-level and incumbent workers the opportunity to demonstrate they have the skills for technology-intensive jobs of the 21st century.

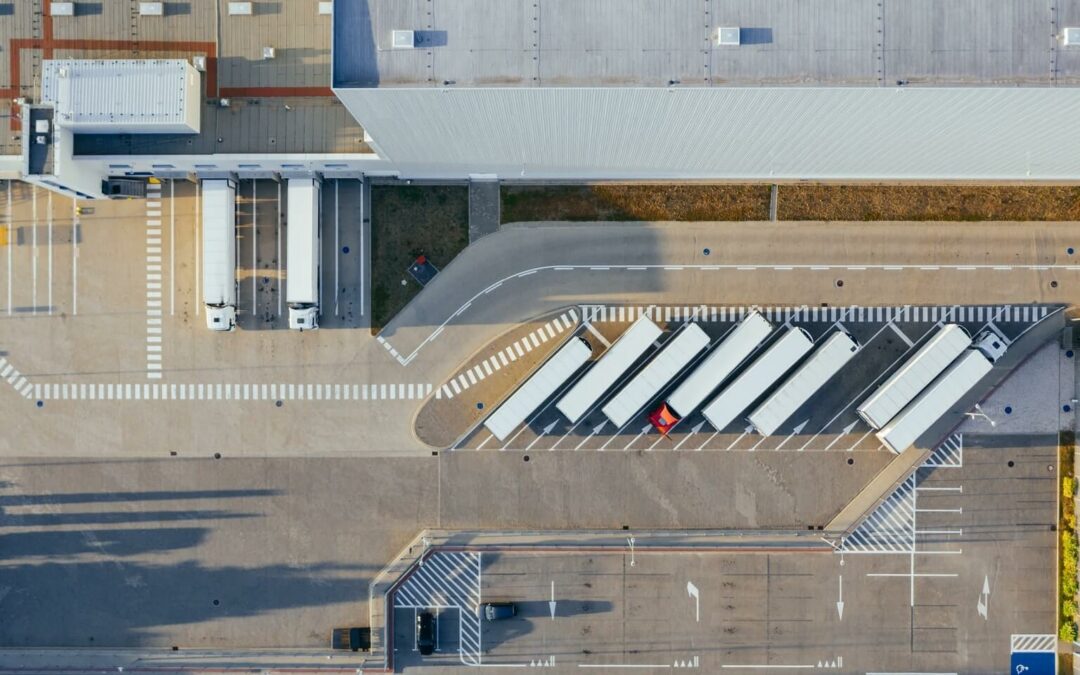

MSSC works with Nocti Business Solutions (NBS) as a key industry partner. NBS helps MSSC maintain its rigorous standards and provides assessment development, maintenance, and delivery. NBS is proud to work with MSSC as they continue to set the quality standards for frontline technicians in our nation’s factories, distribution centers, warehouses, and transportation hubs.

Defining Industry Standards for Manufacturing & Logistics

In 1997, under the National Skill Standards Act, MSSC was tasked with developing industry standards for frontline production workers in advanced manufacturing. The in-depth process to develop these standards involved collaboration with over 700 employers and 2000 workers from all sectors of manufacturing. The input from these frontline workers was critical in identifying, defining, and validating the skills needed for success in manufacturing. In 2007, MSSC went on to develop logistics standards for frontline workers in material handling and distribution.

Each set of standards is organized under two headings: work standards and technician standards.

Work Standards are key activities and performance indicators. These define the work an individual must perform to meet the industry-defined standard.

Technician Standards are basic technical core competencies. These define the knowledge and skills needed to perform the work as defined in the first standard.

The Search for an Assessment Developer

With industry-defined standards in place, MSSC saw an additional need to provide workers a way to document they had the skills and knowledge to meet the standards. Employers also needed a way to validate the skills of both new and incumbent workers. To do this, MSSC needed to find an assessment developer.

MSSC had specific requirements for any potential assessment developers. The standards MSSC had developed would be the foundation for assessments. However, more work was needed to ensure the assessment accurately measured the core skills and competencies and gave a true picture of a test taker’s skills.

Combining our Expertise

As a nationally recognized assessment developer, NBS and its sister organization, NOCTI, had a long history of occupational assessment development. NBS began working with MSSC in 2002 and was instrumental in helping MSSC meet the rigorous requirements set forth by stakeholders in the industry.

For every certification, NBS and MSSC work closely with teams of subject matter experts to develop specific items (questions) for the assessment, pilot test the assessment, conduct psychometric analysis, organize workshops to determine a cut-score, and deliver the assessment. Every year, NBS also helps maintain the assessments by re-analyzing each item to ensure it matches the current industry standard and keeps pace with technological changes.

MSSC’s newest certification, the Certified Technician in Supply Chain Automation, prepares learners for highly technical careers in the logistics sector. These automation technicians are critical as they are the ones who install, operate, support, upgrade, and maintain the equipment and systems in distribution and fulfillment centers. To earn the full certification, learners complete hands-on learning on a “Skill Boss-Logistics” training device, a smaller-scale version of a warehouse that replicates the sorting systems technicians will need to know how to repair.

Making Well-Paying Careers more Accessible

MSSC has partnered with many local and national organizations to make its certifications available to a wide range of job seekers. Many people pursuing certifications are unemployed, active-duty military, currently have low-paying jobs, or those who do not have time or resources for a two or four-year degree. Most who earn an MSSC certification are hired with a $14 to $16/hour starting wage. A study conducted with the National Student Clearinghouse found that most learners who complete the Certified Production Technician program were earning $45 to $50k/year within 3 to 5 years.

MSSC certifications also serve as an introduction to the worlds of manufacturing and logistics, giving learners a foundation on which to build more skills. Those who complete an MSSC program go on to earn welding, machining, mechatronics, and CNC certifications. MSSC certifications help make these well-paying careers accessible to those who may not have otherwise had an opportunity to explore these career paths.

MSSC’s 1900+ assessment centers are located throughout the U.S. in

- Correctional Programs

- Military Bases

- Job Centers

- Career Centers

- High Schools

- Tech Schools

- Community Colleges

Advice for Employers on Closing the Skills Gaps

For those looking to close their skills gap, Neil Reddy, MSSC CEO, advises employers to actively engage their community and to do their homework on the various certifications in the industry. Because standards are a bedrock of a certification, employers should take a more in-depth look to ensure the skills and competencies align with their industry.

Once you have identified certifications relevant to your industry, Reddy also advises employers to let the community know what qualifications you prefer. Many community-based job programs and local schools may wish to offer these certifications to learners. This benefits the community by equipping new workers with relevant skills and helps the employer create a skilled pool of applicants to help close the skills gap and fuel growth.

Equipping a Skilled Workforce

NBS is proud to be helping MSSC toward their ambitious “20/20 vision” of certifying 20% of the nation’s frontline manufacturing production and material handling technicians, or 3 million technicians, by 2030. The technical expertise of MSSC and industry subject matter experts provides the foundation for the most industry-relevant standards possible. Measuring and validating skills against these standards provides proof that technicians are equipped with the required skills for success and will be able to keep pace with technological change. For employers searching for skilled technicians, an MSSC certification is recognizable proof that a candidate has acquired the necessary skills to become a valuable member of their organization.

Reddy commented “Our partnership with Nocti Business Solutions is an integral component to our success. Not only does Nocti lend their expertise in developing new certifications, but they also help us maintain our incredibly high standards, which is a key part of maintaining our ISO accreditation. We might not be in business today if it wasn’t for Nocti.”

Recent Comments